Industries and NDT Applications

UniWest is at the forefront of addressing intricate Non-Destructive Testing (NDT) hurdles across a spectrum of industries, encompassing:

- Aerospace/Aircraft

- Automotive

- Power Generation

- Primary Metals

- Manufacturing

With unparalleled expertise and a robust suite of solutions, UniWest navigates the complexities of NDT with finesse, ensuring the integrity and safety of critical components in these sectors. Our commitment extends beyond industrial applications, as UniWest’s prowess in product and application development resonates across diverse environments including research, training, and laboratory settings.

NDT Solutions for the AEROSPACE industry

UniWest provides the total solution for developing inspection tooling on jet engine and airframe structures. Where safety and reliability are paramount, UniWest’s precise NDT solutions ensure the integrity of critical components, enhancing operational efficiency and minimizing downtime.

UniWest can develop customized special application Eddy Current probes and Ultrasonic transducers in addition to providing instrumentation, special reference standards, and service & support to meet your quality program objectives.

UniWest’s hand-held Eddy Current Testing (ECT) and Non-Destructive Testing (NDT) equipment, such as the EVi eddy current flaw detector and ECS-3 rotating eddy current scanner system, can be used in the field to detect surface and subsurface cracks, heat damage, and variations in thickness and to discover any corrosion in ferrous or nonferrous materials. Our US-525M multi-channel eddy current instrument and UniWest Specialty Probes provide continuous monitoring for material changes in safety-critical parts such as jet engines.

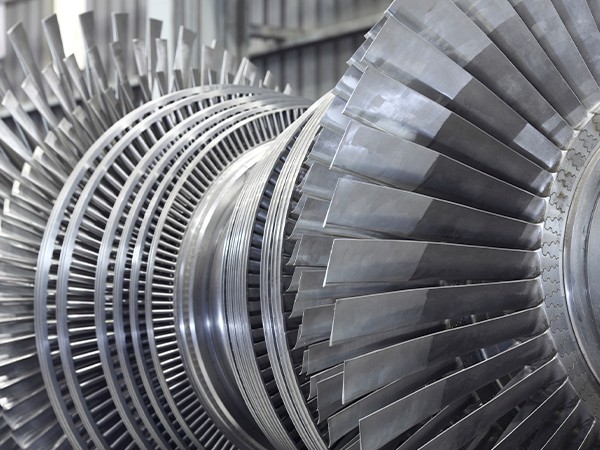

NDT Solutions for the POWER GENERATION industry

Eddy Current & Ultrasonic flaw detection on gas turbines. Power generation facilities rely on UniWest’s robust NDT solutions to maintain the integrity of equipment such as turbines, boilers, and pipelines, ensuring uninterrupted operation and maximizing energy output.

UniWest manufactures specialty sensors and instrumentation for eddy current and ultrasonic inspections, such as location of surface & sub-surface cracks and field measurement of conductive & non-conductive coatings to discover material loss in such parts as turbine blades.

UniWest can assist in the development of your entire inspection tooling system, as well as provide service and support to ensure your inspection teams are providing accurate and repeatable results.

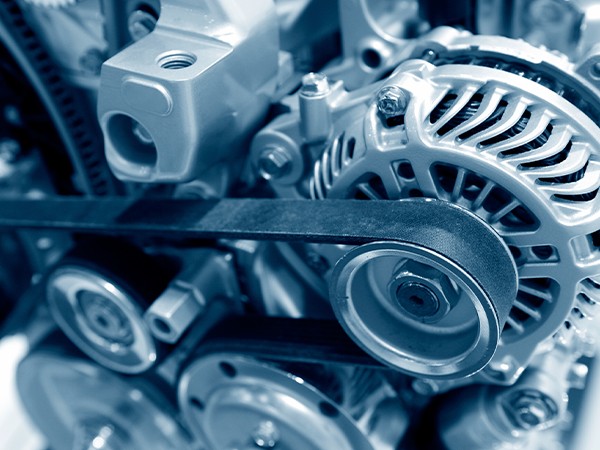

NDT Solutions for the AUTOMOTIVE Industry

Automotive component testing. In the automotive sector, our state-of-the-art testing systems play a pivotal role in quality assurance, enabling manufacturers to detect flaws early in the production process and deliver vehicles that meet the highest standards of performance and safety.

UniWest products can be integrated into your automotive production line to meet your component testing needs. UniWest can develop your entire turnkey system or act as a system integrator for your in-line testing needs.

NDT Solutions for PRIMARY METALS

Material quality verification / positive material identification (PMI). Primary metals manufacturers trust UniWest’s expertise to detect defects in raw materials and finished products, safeguarding against structural failures and optimizing production processes for enhanced efficiency and cost-effectiveness.

UniWest products can assist in your material quality verification process to ensure your products meet high industry standards. UniWest’s EddyView II and EVi eddy current flaw detectors are widely used in this industry to detect porosity and internal discontinuities of cast materials to prevent future cracks and breaks.

NDT Solutions for MANUFACTURING

Non-Destructive evaluation of bar, tube and wire products. Across the manufacturing landscape, UniWest’s comprehensive NDT solutions empower companies to uphold stringent quality standards, streamline operations, and drive innovation.

UniWest can assist with systems integration for on-line non-destructive testing of bar, tube and wire products. Whether you need servicing of your existing NDT inspection system or customized application support, UniWest can offer a turnkey approach to your special testing needs.

Reach Out To Us

Ready for more information or an on-site demonstration?

Click the button below to get started!